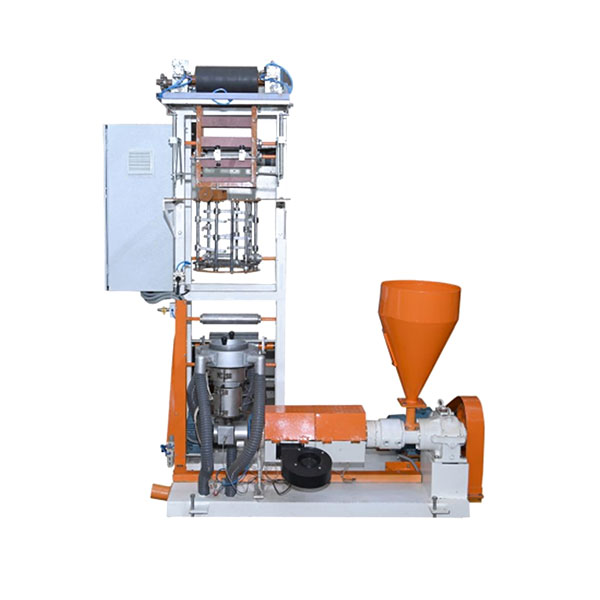

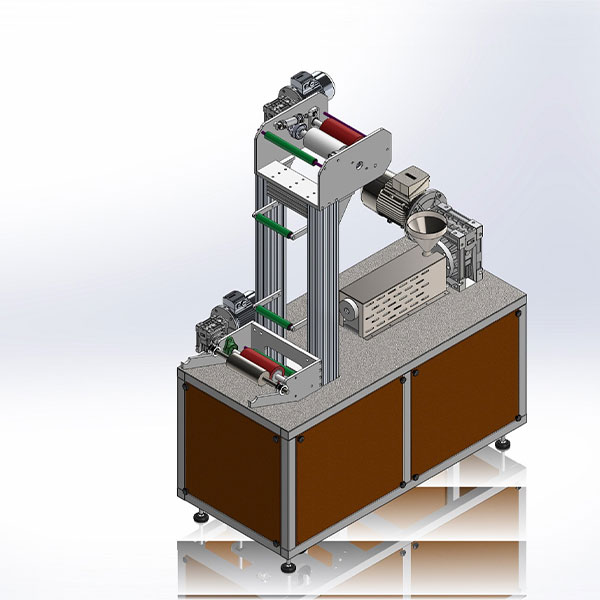

Technical Specification:

| Machine Out Put | 3to 5 Kgs/hour. Depending on material density. |

| Main Motor | 3.7 Kw./ 5 H.P., 1440 RPM, 415 V,50 Hz. |

| AC Frequency Drive | 5 H.P. drive reputed Company make. |

| Gear Box | Helical with hollow output shaft. |

| Screw Dia | 24.9mm |

| Screw RPM | 0 to 75 RPM Speed variation by precise 10 turn potentiometer control |

| Barrel L/D Ratio | 25:1 |

| Compression Ratio | 1:3 |

| Temperature Range | Up to 0 to 300°C |

| Temperature Controller | Auto Tune type PID with Dual Display accuracy ±1°C |

| Hopper Cooling | At feed zone by water. |

| Barrel Temperature Controlling | Barrel cooling by Pressurized Air Blower. |

| Total Numbers of Zone | 6 Nos. (3 Nos. of barrel,1 no. for adaptor and 2 nos. for die) |

| Heating media | S.S. Ceramic bend type heater , 230 V. AC. |

| Total Connecting Electrical Load | 8 Kw. (415 Volts +/- 6%, 50 Hz, 3 Phase with neutral and earthing) |

| Operating Centre height of machine | 600mm (approx.) or can be provide as per customer requirement. |

| Machine Structure | MS structure made from Heavy duty Robust Pipe/Plate or Aluminum profile pipe structure(As per requirement)MS structure made from Heavy duty Robust Pipe/Plate or Aluminum profile pipe structure(As per requirement) |

| Paint | PU Paint or powder coating |

| Utility Scope of Supply require by customer for downstream equipment. | 4 to 6 kg/cm² Pressurized Air and 0.5 to 1 kg/ cm² water pressure require For Downstream accessories. |